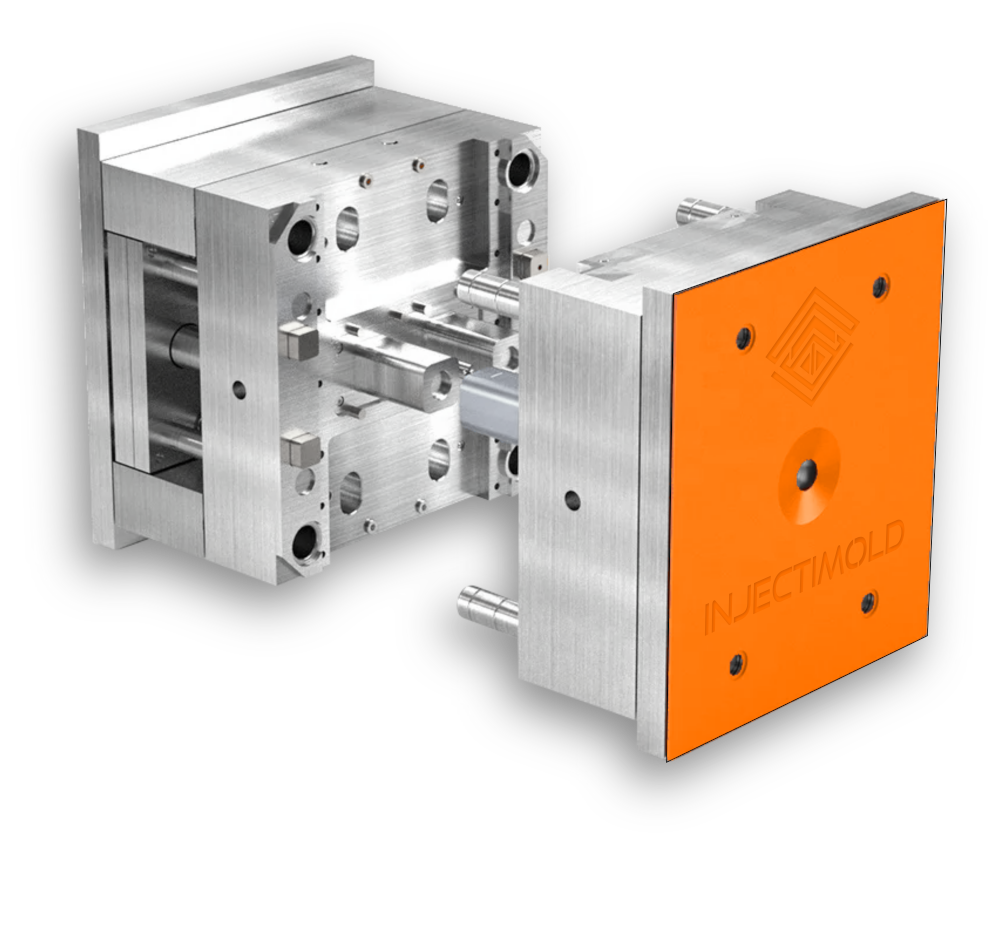

With nearly 50 years of experience in the field of plastic injection molding for automotive, food industry, intralogistics and many other areas, we offer high-quality outsourcing services for all your injection molding projects.

Check conformity of mold and quality of injected parts

Test of raw materials

Samples / Pilot runs

Small series

Large series

No need to invest in costly injection molding machines and production workshop

Produce geographically closer to customers

(relocation of molds)

3 production sites in Luxembourg, Czech Republic and Bulgaria.

2 workshops for manufacturing and repair of molds.

Storage warehouses with more than 5000 pallet spaces.

20 silos for raw materials.

More than 80 injection molding machines from many brands: ENGEL, KRAUSSMAFFEI, BILLION,

HAITIAN, CHEN HSONG and NETSTAL.

Clamping force from 140 to 1100 tons.

Injection volume from 140 to 14000 cm3.

Opening from 400 to 1600 mm.

Expertise in injection of many plastic materials (filled and unfilled polymers): PP (polypropylene), PP V0 (flame retardant polypropylene), RPP (recycled polypropylene), ABS (acrylonitrile butadiene styrene), ABS V0 (flame retardant acrylonitrile butadiene styrene), PC/ABS (polycarbonate and acrylonitrile butadiene styrene), SAN (styrene acrylonitrile), POM (polyoxymethylene)...

Quality analysis laboratories equipped with DSC (differential scanning calorimetry),

TGA (thermogravimetric analysis), MFR (melt flow rate), traction and bending measurement,

aging furnaces, three-dimensional control...

IATF 16949:2016 certification.